When it comes to purchasing a dive kit, choosing a Scuba Diving Regulator can be a daunting task, as it involves selecting from a wide range of aspects, components and technologies, not to mention the cost involved. To help you make an informed decision, let's dive into the technical details of the key features and technologies of a regulator set. This will equip you with the necessary knowledge to make the best choice.

It is recommended for divers to select a primary and octopus regulator from the same manufacturer. This is because the internal pressures of each manufacturer’s regulators can vary slightly, leading to potential incompatibility issues if mismatched. It is crucial for manufacturers to test their regulators as a complete set, ensuring that they meet regulatory standards. Keep in mind that the basic types and concepts for regulator design are universal, but each manufacturer has their own unique spin and naming conventions. The four primary components of a regulator include:

- The First Stage: This is the component that connects to the tank valve and reduces the high-pressure air to an intermediate pressure.

- The Second Stage: This is the component that delivers air to the diver on demand and is known as the primary regulator.

- The Octopus: This is essentially a redundant second stage that is used as a backup in case the primary regulator fails.

- Nitrox Regulators: Recreational diving regulators are good for use with oxygen content up to 40%. For anything above that, you need an oxygen-clean nitrox regulator.

- Air Integration and Gauges: provide critical information to divers regarding their cylinder air supply.

- Hoses: These are the tubes that connect the components of the regulator together and deliver air to the diver.

First Stage

The primary function of the first stage in a diving regulator is to reduce the high-pressure air of up to 300 bar in a cylinder to a lower pressure range of around 9-10 bar, which is then supplied to the second stage regulator when needed. The performance of a first stage is directly proportional to its cost, with more expensive models delivering higher flow rates, quicker response to pressure changes, and advanced features.

There are four primary types of first-stage designs, which differ based on the mechanism used (piston or diaphragm) and whether they are balanced or unbalanced.

Design

Piston and Diaphragm are two different mechanisms that essentially serve the same purpose. However, they both have their own advantages and limitations. Piston first stages are often used in high-performance regulators that boast impressive flow rates and other advanced features. On the other hand, the diaphragm first stages are commonly found in regulators designed for cold and extremely cold water environments due to their increased durability and protection against the elements.

Balancing

Unbalanced first stages offer a cost-effective solution as they are relatively simple in design. However, their performance is influenced by the changes in cylinder pressure and ambient pressure, which can have a negative impact on their efficiency as the pressure drops or when diving deeper. In contrast, balanced systems provide a more reliable and consistent performance by compensating for these factors. This comes at a higher cost due to the increased complexity of their design, but it ultimately results in a more efficient and stable performance.

Fitting

Most regulators offer two options to connect to the cylinder: DIN or A-Clamp/Yoke fitting. DIN is considered a safer alternative as it traps the sealing o-ring, while A-Clamp/Yoke only pushes against it, risking its displacement under pressure. Another advantage of DIN is its ability to be temporarily converted to A-Clamp/Yoke through an inexpensive adaptor, providing the best of both worlds.

Extras

The fundamental components are the building blocks of any diving regulator, and any additional features are purely supplemental. However, while a basic model may perform satisfactorily, advanced high-end regulators offer superior performance and a smoother experience, akin to the difference between driving a standard car versus a top-of-the-line model.

If you are planning to go diving, you may encounter some additional features that can improve your experience.

- One of these features is an environmental seal that protects the internal components of your diving gear from water and cold.

- Another helpful addition is a heat exchanger fin that helps dissipate the cold generated during diving, which reduces the risk of a free flow.

- Swivelling turrets are also available, which allow for extra movement while diving.

- Lastly, to ensure extra protection, you might want to consider a tougher coating, such as Physical Vapor Deposition (PVD), for your diving gear.

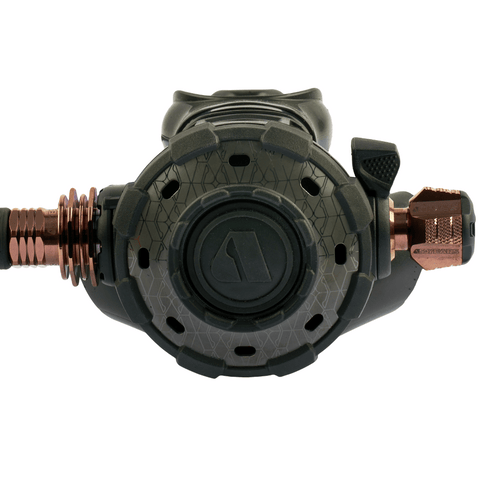

Second Stage

The second stage of a scuba diving regulator is responsible for reducing the intermediate pressure of compressed air to a level that is safe for breathing. There are two main types of valves used for this purpose: downstream unbalanced and balanced valves. Upstream valves are rarely used because they lack an important safety feature that downstream valves provide. In the event of a freeflow situation, downstream valves will be forced open by the increased flow of air, whereas upstream valves will be effectively forced shut, preventing the flow of air altogether. When it comes to the balanced and unbalanced variants of these valves, the same principle applies: a balanced second stage will provide consistent performance throughout the dive.

When it comes to scuba diving regulators, a higher specification second stage with more features is more comfortable to use, but a basic model will still perform the same job. Here are some of the extras that you might encounter:

- Diver Adjustable Inhalation/Cracking Resistance - This feature allows divers to adjust the inhalation effort required to open the valve and let air flow through. More advanced second stages are designed to assist with airflow for a more responsive breathing experience. Keep in mind that the factory default is the optimal setting, and you can only increase the effort required to open the valve.

- Venturi - This feature creates an area of low pressure behind the second stage diaphragm to help pull it inwards, pushing the valve lever down and opening the valve wider. Some regulators have an adjuster, some are automatic, and some are pre-configured.

- Heat Exchangers - Some second stages approved for cold water diving have finned sleeves over the hose inlet to help dissipate the cold in the same way as mentioned for the first stage.

- Metal Components—Some second stages use metal valve barrels and/or housings to improve cold-water performance because metal has a higher thermal transfer characteristic than plastic. As a further upgrade, Carbon-based regulators are lighter than plastic and better at transferring heat than metal.

- Coatings - High-specification models may feature Physical Vapor Deposition (PVD) coated elements to improve their aesthetics and increase resistance against scratches and scuffs.

Octopus

An Octopus is a modified version of a standard second-stage regulator that is equipped with a longer hose to facilitate easier air sharing with a dive buddy in an out-of-air situation. It also features high-visibility yellow panels for better visibility underwater. When purchasing an octopus regulator, one might be tempted to choose the cheapest option available, but it is important to consider the circumstances under which it is likely to be used. In an out-of-air situation, the recipient may not be completely calm and may be breathing at a higher rate than normal until the situation is under control. Therefore, it is recommended to opt for an octopus with reasonable performance and flow rates to ensure that the dive buddy can breathe comfortably.

In technical diving, whether exploring caverns, wrecks, or the depths, it's a standard practice for divers to equip themselves with two high-performance regulators for both the primary and octopus setups. This intentional redundancy ensures that, in the event of an emergency, divers have access to a backup regulator capable of adequately supporting two individuals breathing from a single system. The rationale behind this is straightforward yet crucial for safety: in high-stress situations, especially in environments that are inherently more challenging and potentially hazardous, the reliability and performance of your equipment can be the difference between a controlled resolution and a critical incident. By selecting two high-performance regulators, divers prioritize safety.

Nitrox / Enriched Air Regulators

If you plan on diving with nitrox / enriched air gas mixes, you are going to need to take note of the out-of-the-box oxygen compatibility percentage. Most regulators are compatible with an oxygen content of up to 40%, which will be more than sufficient for most divers. Beyond that point, you'll need to look for a dedicated Nitrox Regulator that is compatible with oxygen percentages of up to 100%. This is especially important for divers engaging in extended-range or technical dives where higher oxygen percentages are utilized to shorten decompression times. Always ensure that your choice of a regulator is not just based on compatibility but also on reliability and performance under the specific conditions you plan to explore.

It is important to mention that in Europe, nitrox regulators used with Oxygen contents above 40% must adhere to specific safety standards, including being color-coded. Additionally, these regulators are required to have an M26 fitting included in the set. This European standard is designed to minimize the risk of incorrect assembly and to ensure the safe usage of high-oxygen-content gases by divers. The colour-coding and the M26 fitting serve as visual and physical cues, respectively, helping to prevent any potential mix-ups that could lead to dangerous situations underwater.

Gauge and Air Integration

All divers will use some sort of simple gauge or a console for the tank pressure monitoring. Nonetheless, many divers today prefer to use air-integrated dive computers, which require mounting a pressure transmitter on the first stage. Air integration allows for better air supply management by displaying pressure and remaining air time directly on the wrist-mounted computer. Each brand produces its own dedicated transmitters, most of which use radio waves to transmit data. However, Garmin stands out with its use of ultrasonic wave technology, which has a better range and allows for limited computer-to-computer communication. This unique feature makes Garmin transmitters a top choice among divers who prioritize advanced technology and communication capabilities.

There are two types of diving air-integration technology:

- Radio Waves based technology is used by major brands such as Suunto, Mares, Shearwater, Scubapro, Aqualung and Apeks

- Ultrasound SubWave technology is used only by Garmin Dive Computers

Regulator Hoses

Not all regulator hoses are created equal! While traditional rubber hoses have been the standard for scuba regulators, the trend has shifted towards lighter, more flexible alternatives. Many manufacturers now prefer braided hoses, which are not only lighter but also more resistant to kinks and abrasions. However, companies like Scubapro still utilize dedicated rubber hoses with a larger internal diameter. This choice is purposeful, aiming to achieve higher airflow rates, which improves gas delivery and reduces breathing effort, especially at greater depths where breathing can become more laborious.

- There are three types of regulator hoses commonly used in the industry. The first type is the basic rubber hose, which is heavy and stiff and tends to deteriorate when exposed to elements like UV.

- The second type is rubber hoses with a larger internal diameter, also known as superflow or something similar. Although they have the same construction and problems as rubber hoses, the larger internal diameter offers better performance and flow rates.

- Finally, braided hoses are the third type. They are much lighter, have a higher burst pressure, improve safety, and are more flexible and resistant to UV and contamination damage. Due to these benefits, manufacturers are increasingly fitting braided hoses as standard.

At this point, you likely have a comprehensive understanding of the core concepts that will empower you to pick the perfect regulator for your diving preferences. Experienced divers would recommend investing in a high-quality regulator that is within your budget. However, if you still have doubts about which regulator to opt for, please feel free to connect with our support team for expert advice. We are committed to assisting you in accomplishing your diving objectives